LOW TEMPERATURE CURE INJECTABLE VINYLESTER RESIN

X2000 380ML

Cold weather concrete block anchor resin

X2000 is the solution for cold weather adhesive anchoring applications in uncracked concrete. Fast curing is the feature of Vinyl ester. Save time to achieve high bonding strength. No styrene and VOC approval qualified for environmentally friendly and green house. Excellent in acid-resisting, alkali-resisting for chemical industry installation.

A two-component 10:1 resin chemical anchoring injection system. Convenient setting and fast curing in low temperature. All of our products had tested and approved in Germany according to EAD 330499-00-0601. Vinylester anchor mortar is available for fixings on non-cracked concrete, masonry, brick, stone, perforated brick. There are also 150ml, 235ml, 345ml and 360ml for diverse market preference.

Chemical fixing system – Fast curing viny lester chemical anchor

The obvious characteristic of vinylester hybrid mortar is fast curing to save installation time and hardening time. We develop diverse curing time to meet different country weather and installation temperature. Fast curing formula is not suitable for nonstandard high temperature which caused curing time accelerated. Please check technical data sheet for safety installation.

Specification of X2000 vinylester chemical anchor

- Material: Vinylester Styrene Free

- Model Number: X2000

- Size: 380ml

- Shelf Life: 18 months

- Mixing Ratio: 10:1

- Mixed Color: Gray

- Standard Package: One cartridge with one mixer

- Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Vinylester chemical anchor provide excellent bonding strength in cold weather

- Suitable for cold weather application

- Provide maximum flexibility and efficiency

- Fast curing time

- Styrene free and low odor with VOC certificate

- Excellent acid and alkali resistance

- ECO friendly building material

Winter version vinylester injection hybrid styrene free adhesive

X2000 winter version is developed principally to low temperature anchoring. It still provides fast curing time and high bonding strength for threaded stud bolts and rods. For applied to solid elements, such like concrete, stone, cement, and wood. It’s very good chemical resistance to acid and alkali environment. In 10-20℃ working place, the gelling time is 5min and full curing time is 35min.

Technical Data

CHART 1. SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) |

Safety Haul Strength (Kgf/KN) |

Working Standard (mm) |

||||||

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. | #3 | (Φ10) | 3,540 | 35.8 | 1,180 | 11.9 | 13 | 90 | |

| #4 | (Φ13) | 5,490 | 55.4 | 1,827 | 18.5 | 16 | 120 | ||

| #5 | (Φ16) | 9,060 | 91.5 | 3,020 | 30.5 | 20 | 145 | ||

| #6 | (Φ19) | 14,150 | 142.9 | 4,717 | 47.6 | 25 | 170 | ||

| #7 | (Φ22) | 18,630 | 188.2 | 6,210 | 62.7 | 28 | 200 | ||

| #8 | (Φ25) | 23,195 | 234.3 | 7,732 | 78.1 | 32 | 225 | ||

| #9 | (Φ29) | 25,340 | 256.0 | 8,447 | 85.3 | 37 | 250 | ||

| #10 | (Φ32) | 32,120 | 324.4 | 10,707 | 108.1 | 40 | 290 | ||

| Remarks: | 1. Concrete Strength fc’: 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CHART 2. CURING TIME TABLE

| Cartridge temperature (Mortar) | Gelling time | Temperature at anchoring base |

Curing time |

| -15℃ – -10℃ | 15 hours. | ||

| -10℃ – -5℃ | 10 hours. | ||

| -5℃ – ±0℃ | 15 min. | -5℃ – ±0℃ | 4 hours. |

| -±0℃ – +5℃ | 10 min. | -±0℃ – +5℃ | 1 hour 40 min. |

| +5℃ – +10℃ | 6 min. | +5℃ – +10℃ | 50 min. |

| +10℃ – +20℃ | 5 min. | +10℃ – +20℃ | 35 min. |

| Remarks: |

1. Without approval |

||

CHART 3. FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings | ||||

| 235ml | 280ml | 345ml | 360ml | 380ml | |||

| M8 | 10 | 80 | 47 | 56 | 69 | 72 | 76 |

| M10 | 12 | 90 | 29 | 34 | 42 | 44 | 47 |

| M12 | 14 | 110 | 17 | 21 | 25 | 27 | 28 |

| M16 | 18 | 125 | 9 | 11 | 14 | 14 | 15 |

| M20 | 24 | 170 | 4 | 5 | 6 | 6 | 6 |

| M24 | 28 | 210 | 2 | 3 | 3 | 4 | 4 |

| M30 | 35 | 270 | 1 | 1 | 2 | 2 | 2 |

| M36 | 40 | 330 | 1 | 1 | 1 | 1 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||||||

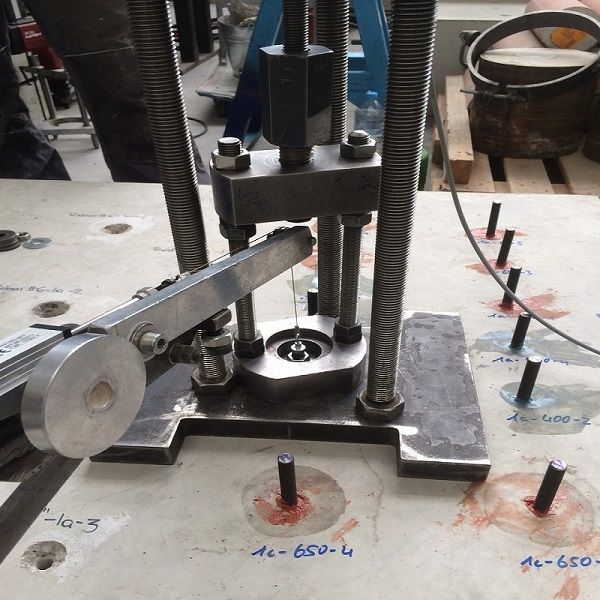

How to install chemical anchor?

1. Drill the specific hole size and depth. 2. Clean dust with brush and air blow pump. 3. Press out unmixed resin which can’t be used. 4. Inject mixed resin into drilled hole and fill from the bottom. 5. Insert rebar/threaded rod/steel strip. Curing time refer to TDS. Don’t touch until full curing. The installation process will affect the bonding performance of chemical anchors.