360ML ANCHORING SYSTEM POLYESTER CHEMICAL ANCHOR

X100 360ML

Adhesive mortar anchoring chemical fixings

360ml polyester chemical anchor is middle size and more flexible in market. It needs a specific caulking gun to extrude the mortar.

Polyester with styrene chemical anchor is classic and most popular material for general purpose. Economical price satisfies most fixing demands of medium loads. Applicable for rebar doweling, handrail, facade, pipelines, awnings, brackets. All of our chemical anchor had tested and approved in Germany according to EAD 330499-00-0601. There are also 150ml, 235ml, 345ml and 380ml available in the range.

Chemical fixing system – Economical polyester with styrene

Easy setting injectable mortar for anchoring in concrete and for rebar connections. Market-oriented that we offer various volumes and cartridge design for all kinds of consumption. 150ml is co-axial cartridge with mixing ratio 10:1 for standard silicone gun which no extra dispensing tool required and satisfied one time using. 235ml is best selling size in Taiwan. Middle size of 345ml and 360ml are most popular for flexible applications. 380ml co-axial is economic volume for construction. Polyester injectable adhesive is best choice for beginner to meet mostly basic fixing demands.

Specification

- Material: Polyester with styrene

- Model Number: X100

- Size: 360ml

- Shelf Life: 12 months

- Mixing Ratio: 10:1

- Mixed Color: Gray

- Standard Package: One cartridge with one mixer

- Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Features & Benefits

- Loading strength approved by Germany lab.

- No expansion effect, allowing fixing close to the edges.

- Low levels of volatile organic compounds (VOC’s) according to LEED test.

- Cost-efficient and long durability.

- Vertical or horizontal fixings.

- Medium loads for general anchoring purpose.

- Private label or customized design by demands.

Polyester for structure connect system, market-oriented and cost-effective formula

Connect new struction or extension parts to old building which is required high vertical or horizontal loading capacity. With anchoring resin reinforce the structure connections steadily and durability. For general application of fixture, polyester is acceptable price and satisfied performance for most demands. It’s common, mature item and widely apply to construction.

Technical Data

CHART 1. SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) |

Safety Haul Strength (Kgf/KN) |

Working Standard (mm) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. |

#3 | (Φ10) | 3,070 | 31.0 | 1,023 | 10.0 | 13 | 90 | |

| #4 | (Φ12) | 4,920 | 49.7 | 1,640 | 16.6 | 16 | 120 | ||

| #5 | (Φ16) | 6,800 | 68.7 | 2,267 | 22.9 | 20 | 145 | ||

| #6 | (Φ20) | 7,708 | 77.9 | 2,569 | 25.9 | 25 | 170 | ||

| #7 | (Φ22) | 9,440 | 95.4 | 3,147 | 31.8 | 28 | 200 | ||

| #8 | (Φ25) | 13,620 | 137.6 | 4,540 | 45.9 | 32 | 225 | ||

| #9 | (Φ29) | 20,340 | 205.6 | 6,780 | 68.5 | 37 | 250 | ||

| #10 | (Φ30) | 26,620 | 269.0 | 8,873 | 89.6 | 40 | 290 | ||

| Remarks: | 1. Concrete Strength fc’: 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CHART 2. CURING TIME TABLE

| Temperature (°C) | Gelling | Full Curing |

| 0~5 | 8 hr. | |

| 5~10 | 40 min. | 7 hr. |

| 10~20 | 30 min. | 6 hr. |

| 20~30 | 8 min. | 3 hr. |

| 30~40 | 3 min. | 2 hr. |

| Please make pull out test over 24 hours after full cured. | ||

CHART 3. FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings | ||||

| 235ml | 280ml | 345ml | 360ml | 380ml | |||

| M8 | 10 | 80 | 47 | 56 | 69 | 72 | 76 |

| M10 | 12 | 90 | 29 | 34 | 42 | 44 | 47 |

| M12 | 14 | 110 | 17 | 21 | 25 | 27 | 28 |

| M16 | 18 | 125 | 9 | 11 | 14 | 14 | 15 |

| M20 | 24 | 170 | 4 | 5 | 6 | 6 | 6 |

| M24 | 28 | 210 | 2 | 3 | 3 | 4 | 4 |

| M30 | 35 | 270 | 1 | 1 | 2 | 2 | 2 |

| M36 | 40 | 330 | 1 | 1 | 1 | 1 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||||||

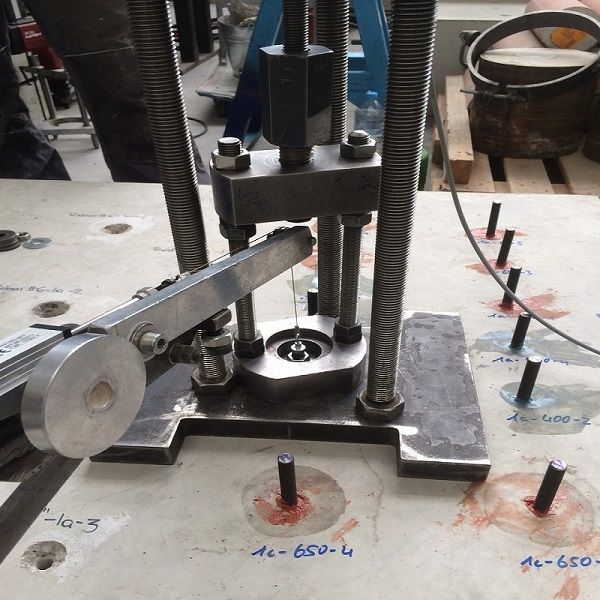

How to install chemical anchor?

1. Drill the specific hole size and depth. 2. Clean dust with brush and air blow pump. 3. Press out unmixed resin which can’t be used. 4. Inject mixed resin into drilled hole and fill from the bottom. 5. Insert rebar/threaded rod/steel strip. Curing time refer to TDS. Don’t touch until full curing. The installation process will affect the bonding performance of chemical anchors.