235ML ANCHOR SYSTEM EPOXY ACRYLATE CHEMICAL ANCHOR

X600 235ML

Fast gelling time epoxy acrylate anchoring resin

235ml is small volume and good for home DIY with quick setting time. It is convenient to operate the bonded anchor system and best selling at hardware store or online shop.

X600 injection bonded resin is middle to heavy strength for extensive loads requirements. All of our products had tested and approved in Germany according to EAD 330499-00-0601 which is norm of bonded fasteners for use in concrete. There are also 150ml, 345ml, 360ml and 380ml available in the range.

Chemical fixing system – Acid and alkali-resisting epoxy acrylate chemical anchor

For anchoring structural steel connections at specific environment of acid and alkali. We will suggest to apply X600 Epoxy acrylate with styrene or X2000 without styrene. All of our injectable cartridge mortar tested in European lab to approval the performance on structural connections with post-installed rebar and threaded anchor.

Specification of X600 epoxy acrylate chemical anchor

- Material: Epoxy Acrylate with styrene

- Model Number: X600

- Size: 235ml

- Shelf Life: 18 months

- Mixing Ratio: 10:1

- Mixed Color: Gray

- Standard Package: One cartridge with one mixer

- Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Features & Benefits

- Medium heavy load and economical choice.

- Resistance to acid and alkali. and low VOC.

- Easy and quick use, less waste.

- Uses standard sealant gun.

- Cartridge reusable by simply exchanging static mixer.

Fast curing and easy setting two part epoxy acrylate adhesive

X600 is a two component adhesive of styrene epoxy acrylate for use in concrete and masonry. It is designed as quick setting and fast curing for high loads fixing and time sensitive applications especially for threaded rob anchoring and rebar dowelling. 235ml epoxy acrylate anchor system has great peformance for fixing into hollow materials, prefabricated concrete structures, solid concrete, granite, and natural stone.

Technical Data

CHART 1. SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) | Safety Haul Strength (Kgf/KN) | Working Standard (mm) | ||||||

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. | #3 | (Φ10) | 3,622 | 36.6 | 1,207 | 12.2 | 13 | 90 | |

| #4 | (Φ12) | 6,437 | 65.0 | 2,146 | 21.7 | 16 | 125 | ||

| #5 | (Φ16) | 9,737 | 98.4 | 3,246 | 32.8 | 20 | 145 | ||

| #6 | (Φ20) | 13,715 | 138.5 | 4,572 | 46.2 | 25 | 170 | ||

| #7 | (Φ22) | 18,754 | 189.4 | 6,215 | 63.1 | 28 | 200 | ||

| #8 | (Φ25) | 24,137 | 243.8 | 8,046 | 81.3 | 32 | 225 | ||

| #9 | (Φ28) | 27,484 | 277.6 | 9,161 | 92.5 | 37 | 260 | ||

| #10 | (Φ32) | 31,869 | 321.9 | 10,623 | 107.3 | 40 | 290 | ||

| #11 | (Φ36) | 36,000 | 363.6 | 12,000 | 121.2 | 42 | 320 | ||

| Remarks: | 1. Concrete Strength fc’: 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CHART 2. CURING TIME TABLE

| Temperature (°C) | Gelling | Full Curing |

| 5~9 | 2 hr. | 90 hr. |

| 10~14 | 90 min. | 64 hr. |

| 15~19 | 45 min. | 28 hr. |

| 20~29 | 30 min. | 18 hr. |

| 30~39 | 20 min. | 7 hr. |

| 40 | 12 min. | 5 hr. |

| Please make pull out test over 24 hours after full cured. | ||

CHART 3. FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings |

| 400ml | |||

| M8 | 10 | 80 | 80 |

| M10 | 13 | 90 | 42 |

| M12 | 16 | 120 | 21 |

| M16 | 20 | 145 | 11 |

| M20 | 25 | 170 | 6 |

| M24 | 28 | 210 | 4 |

| M30 | 35 | 270 | 2 |

| M36 | 40 | 330 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||

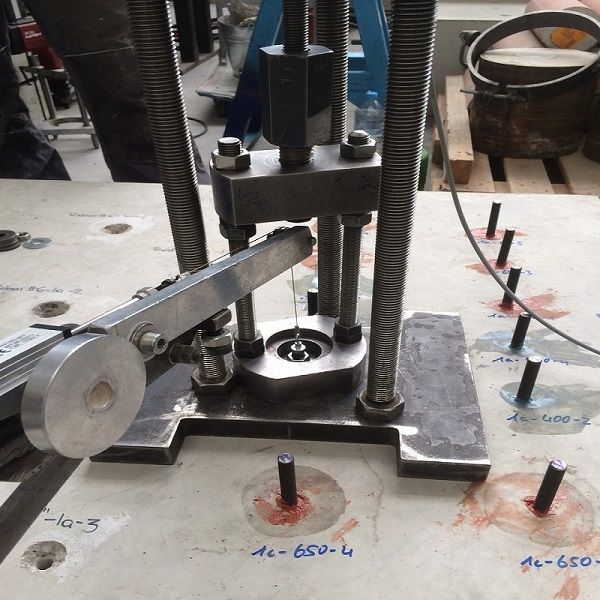

How to install chemical anchor?

1. Drill the specific hole size and depth. 2. Clean dust with brush and air blow pump. 3. Press out unmixed resin which can’t be used. 4. Inject mixed resin into drilled hole and fill from the bottom. 5. Insert rebar/threaded rod/steel strip. Curing time refer to TDS. Don’t touch until full curing. The installation process will affect the bonding performance of chemical anchors.